Q2HB34MB is a constant angle and constant torque stepper drive. It can match 6 or 8 leads 2-phase Hybrid stepper motors whose rated current is under 3A and shaft diameter range from 42mm to 86mm. Owe to bipolar constant chopping circuit, it can make the motor low noise, operated smoothly. It is widely used in the small size of numerical control device with higher resolution such as carving machine, laser labeling machine, inner laser curving machine and etc.

Features

● High performance, low price

● 4 channels constant angel and constant torque subdivision, highest subdivision: 64

● Highest response frequency: 200Kpps

● The motor phase current is reduced to approximately 50% of the set current value 100ms after receiving the last pulse edge

● Bipolar constant current chopping circuit

● Opto-isolated input/output

● Driven current is adjustable continuously from 0.5A/phase to 3A/phase

● Single power supply, voltage arrange from DC12 to 40V

Parameter switches

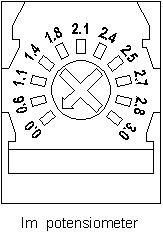

Rotary switch for adjustment of the motor current

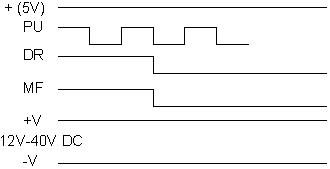

Input signal osillogram

Caution

1. Please don’t reverse the power supply, supply voltage shouldn’t exceed DC40V.

2. Input control signal is 5V., current-limiting resistance should be connected when over 5V.

3. Alarm indicator lights and the drive shuts off if the drive temperature is over 70℃. It doesn’t work until the temperature falls to 50℃. The heat sink is needed when overheat occurs.

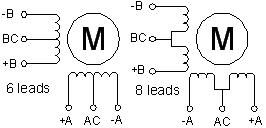

4. 6 or 8 leads motors have to be used because of the special control circuit in the drive.

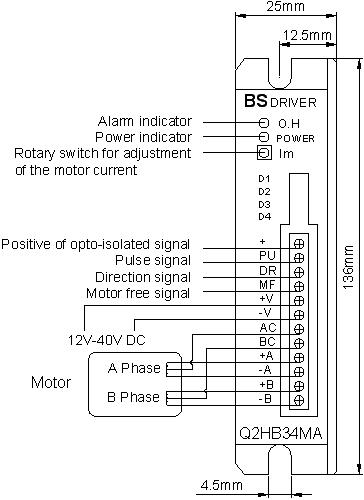

Wiring example

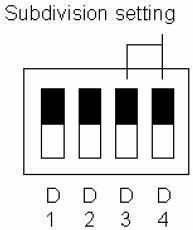

Subdivision setting

|

STEP/REV

|

400

|

1000

|

2000

|

4000

|

|

D4

|

ON

|

OFF

|

ON

|

OFF

|

|

D3

|

ON

|

ON

|

OFF

|

OFF

|

Terminal function

|

Mark

|

Function

|

Specification

|

|

POWER

|

Power indicator

|

The indicator lights when the power is on.

|

|

O.H

|

Alarm indicator

|

The red LED lights when overheat occurs.

|

|

Im

|

Rotary switch for adjustment of the motor current

|

Adjust motor’s phase current. Turning it in CCW will decrease the current and turning it in CW will increase the current.

|

|

+

|

Positive of opto-isolated

|

Connected to +5V power supply. Driven voltage range from +5V to +24V. Current-limiting resistance is needed when over 5V.

|

|

PU

|

Pulse signal

|

With the falling edge of the signal PU, the motor executes an angular step. The input resistance is 220Ω. Low voltage 0-0.5V, high voltage 4-5V, pulse width>2.5μS.

|

|

DR

|

Direction signal

|

Change the motor’s direction of rotation. Input resistance is 220Ω. Low voltage 0-0.5V, high voltage 4-5V, pulse width>2.5μS

|

|

MF

|

Motor free signal

|

The motor current will be cut off and the drive stops working when it effects.

|

|

+V

|

Positive of power

|

DC12V-40V

|

|

-V

|

Negative of power

|

|

AC、BC

|

Connection

|

|

|

+A、-A

|

|

+B、-B

|